Promoting R&D

We have gathered a great deal of know-how over the last 50 years, such as a comprehensive understanding of welding processes, the design and mechanical engineering of tools and knowledge of electronics and the development of software. Our Design Office engineers and technicians have increased our capacity for innovation, as can be seen by our ever more successful, reliable and easy to use solutions.

Taking quality one step further

POLYSOUDE has been ISO 9001 certified since April 2006. This certification strictly defines the approach we take towards the continuous improvement of our quality systems, our products and the services, which we offer our customers. It also applies to the first-class tools we have installed to meet our specific needs, such as our Intranet, TDMS, CAD, CAM, ERP and CRM.

Latest achievements

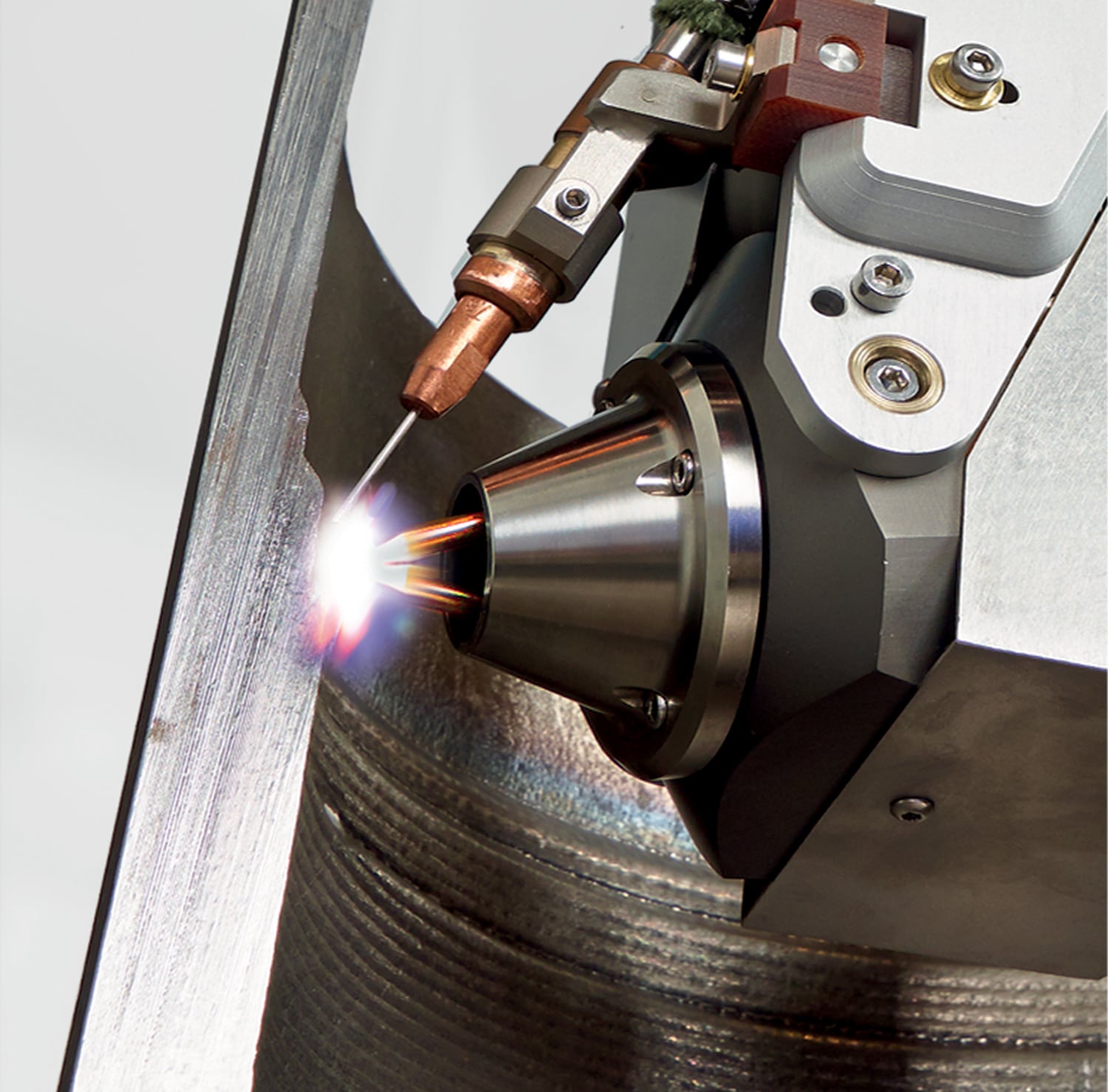

POLYSOUDE’s iconic invention, the TIGer technology, has resulted from another technological development back in 2013. It is a variant of the Hot Wire TIG welding principle. A significant amount of investigation enabled us to define the combination of optimum operating conditions and torch design required to obtain the best levels of performance. The basic principle involves the juxtaposition of two TIG arcs, arranged and controlled, to combine into a single arc with the calorific value of the combination of both powers, but with characteristics which are unusual for such intensities. Indeed, depending on the position of the two electrodes, it is possible to considerably reduce fusion of the base metal, to arrive at dilution rates which makes the TIGer perfectly suited for use in surfacing applications.