EVERYTHING YOU NEED FOR WELD OVERLAY/CLADDING

Solutions for weld overlay and automated cladding operations used in manufacturing and maintenance

Many industrial processes cause damage to piping and fittings by the continuous assault of corrosive and abrasive media. In oil and gas production, for example, components are severely eroded by the friction of sand; chemical apparatuses suffer from direct contact with aggressive substances. These phenomena are often boosted by elevated process temperature and pressure.

What is overlay welding?

Definition: A weld overlay is a type of cladding that uses a welding process to melt a material onto the surface of another, different material. A weld overlay is performed to protect the base material from wear or corrosive environments.

What is the difference between cladding and overlay?

The main difference between cladding and weld overlay is that weld overlay (by codes and standard definition) is deposited by a fusion welding process, and not applied by mechanical methods. Weld overlay can be used to restore structural integrity, corrosion protection, hard facing to deter wear and abrasion.

What is overlay metal?

Weld metal overlaying is a low-cost way for manufacturers to retain the desirable properties of both the base metal and the stainless steel veneer. The process also is highly customizable, allowing manufacturers to choose from a broad selection of materials to layer and alloy multiple surfaces together.

Learn more about cladding:

To increases the durability of these highly exposed parts, their surfaces are protected by cladding with more resistant materials.

- Cladding is applied whenever a long service life is expected from expensive components or when the workpiece cannot be produced entirely from the proper wear-resistant material.

- Cladding of piping and manifolds is common in petrochemical industry applications and for power plant equipment; in the aeronautic industry, components for aircraft engine components are also often reinforced using this process.

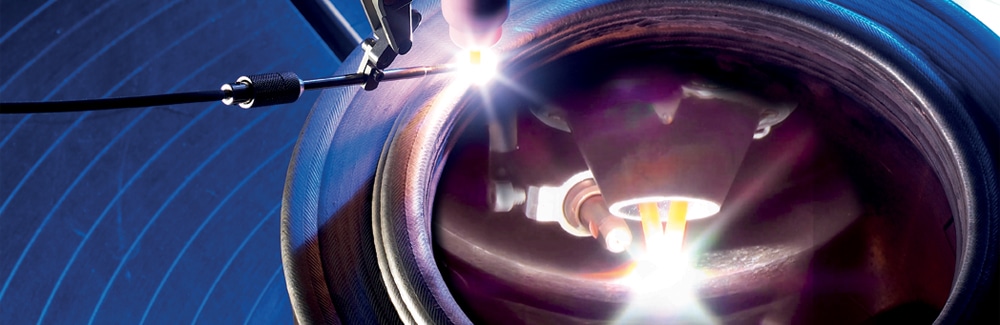

- The TIGer technology is the outcome of a technological development by POLYSOUDE, a variant of TIG Hot Wire cladding. The basic principle involves the juxtaposition of two TIG arcs, organised and controlled to be combined into one single arc with the calorific value of the combination of both powers, but with characteristics which are unusual for such intensities.

- The addition of the wire, preheated using the Joule effect via the control of a third current source, enables the special profile of the weld pool to be used and to considerably improve the efficiency of the procedure.

- Depending on the requirements, it is possible to optimise the thickness of the layers to within a range between 1.5 and 3.5mm. This flexibility enables the quantity of weld metal to be adjusted to strict requirements and thus significant savings can be made, taking into account the costs of filler products (generally the noble alloys). The optimised welding speeds run from 500 to 1000 mm/min with deposition rates from 2.5 to 6kg/h i.e. about three times more than the TIG Hot Wire technology.

- Complete control over dilution is provided with a rate of around 12% on the first layer and from 1.5 to 2% from the second layer.