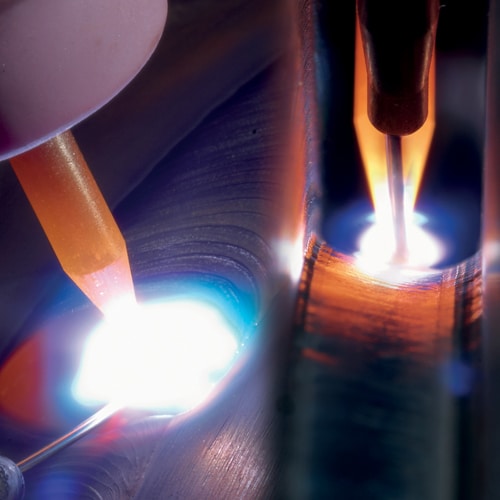

Tests on the new TIGer technology have been conducted by the Italian Welding Institute. Developed, manufactured and provided by Polysoude, specialist in orbital welding and in the construction of automated and robotic welding and cladding equipment, TIGer (Fig.1) has been developed from HW TIG/GMAW technology.

Hot wire technology is already used extensively in the cladding field. It consists of the preheating of a filler material, usually wire, by Joule effect due to the current. This condition reduces the quantity energy taken from the electrical arc, which is required to melt the wire, consequently the efficiency of the thermal source is improved by assuring increased productivity in terms of welding speed and deposit rate, so that a better joint of the welding seam is achieved.