Author: Stagiaire Communication

Polysoude in the news: TIG welding in the Oil & Gas industry

Polysoude Sales Awards 2017

Polysoude at Beijing Essen Welding and Cutting fair 2017

Held every year in China, the Beijing Essen Welding and Cutting fair is renowned as one of the top two welding shows in the world. For this year edition from June 27th to June 30th 2017, Polysoude Shanghai will be once again present to exhibit our latest innovations in welding and cladding technologies.

Address:

Shanghai New International Expo Centre.

No. 2345 Longyang Road, Pudong New Area Shanghai P.R.C. 201204

Polysoude stand n°: Hall N2, N2442

Your Polysoude contact for this event is:

Jianming PAN

jm.pan@polysoude.cn

+138 1782 5399

We are looking forward to welcoming you at our stand!

Polysoude has been published in the EHEDG yearbook 2017/2018

The European Hygienic Engineering & Design Group network (EHEDG) provides a forum for food processing equipment manufacturers, users, legislators and institutes to discuss issues concerning hygienic design and to stimulate food safety.

Polysoude has been a member of the EHEDG organisation since 2010. For every edition of the EHEDG yearbook Polysoude submits contents discussing the latest evolutions in welding technology for the high purity industries. We were again chosen for publication in the 2017/2018 edition. Our article "The key to quality" relates how manufacturers can meet hygienic security specifications with automated orbital welding equipment.

To read "The key to quality" article: click here

To consult the EHEDG yearbook 2017/2018: click here

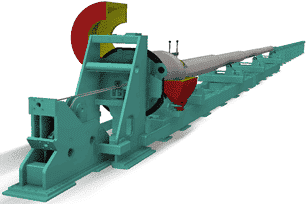

Successful riser test with the “Cladiator” by Polysoude

For the Appomattox project of Shell Houston, Polysoude and SME Cladding BV joined their forces and knowledge to develop an internal bore cladding machine for a riser up to a length of 19 meters and weight of 25 T.

Bringing ID-cladding up to the next level, the installation called ‘Cladiator’ has been developed and manufactured by Polysoude. All the five risers for the project have been completed without any defects and in record time:

- Welding speed = 800mm/min

- Around 70hours to clad 1 riser of around 17,5m length with 2 layers (1,5mm and 2,2mm thickness respectively)

Polysoude Sales Awards 2017

The 2017 (1st edition) of the Polysoude Sales Awards recognised the year’s best achievements in sales, business development and customer service. The awards were presented by Mr Hans-Peter Mariner, CEO of Polysoude and hosted at the Polysoude headquarters in Nantes, France on the 31st of March.

First Edition of the Polysoude Sales Awards

On Friday, March 31st 2017 the first ever Polysoude Sales Awards were held. This ceremony recognised the year’s best achievements in sales, business development and customer service. The awards were presented by Mr. Hans-Peter Mariner, CEO of Polysoude and hosted at the Polysoude headquarters in Nantes, France.

The ceremony was an excellent opportunity to reward the highest performing sales teams for their remarkable contribution, in collaboration with their colleagues in Nantes. In the Orbital Standard Sales category, the 3 strongest performers were GMT (Japan), Chemiko (South Korea) and Polysoude Austria. In the automated welding and cladding category, the winner was Polysoude Italy. And finally, Polysoude UK was given an award for their remarkable development in customer services during 2016.

Sustaining safe welding operations

Borja Saíz Sánchez (Newtesol, Spain) and Jürgen Krüger (Polysoude, France) explain how weld overlay cladding of components can help to guarantee zero defect manufacturing of pipes. Modern oil and gas pipelines are especially assembled for the oil and gas market manufactured line pipe and further components like flanges, fittings, branch pieces (Tees) etc. To absorb the induced mechanical stresses, most of these parts consist of high strength low alloy steel (HSLA). If increased corrosion resistance is required, the interior can be reinforced by a CRA coating. CRA stands for Corrosion Resistant Alloy, this group of materials consists of austenitic and martensitic stainless steels as well as nickel-base and titanium-base alloys.

Hand in hand… Polysoude and T.Drill

The only way to extrude manifolds and automatically weld the nozzles.

You can see the video below:

Video courtesy of Teknohaus